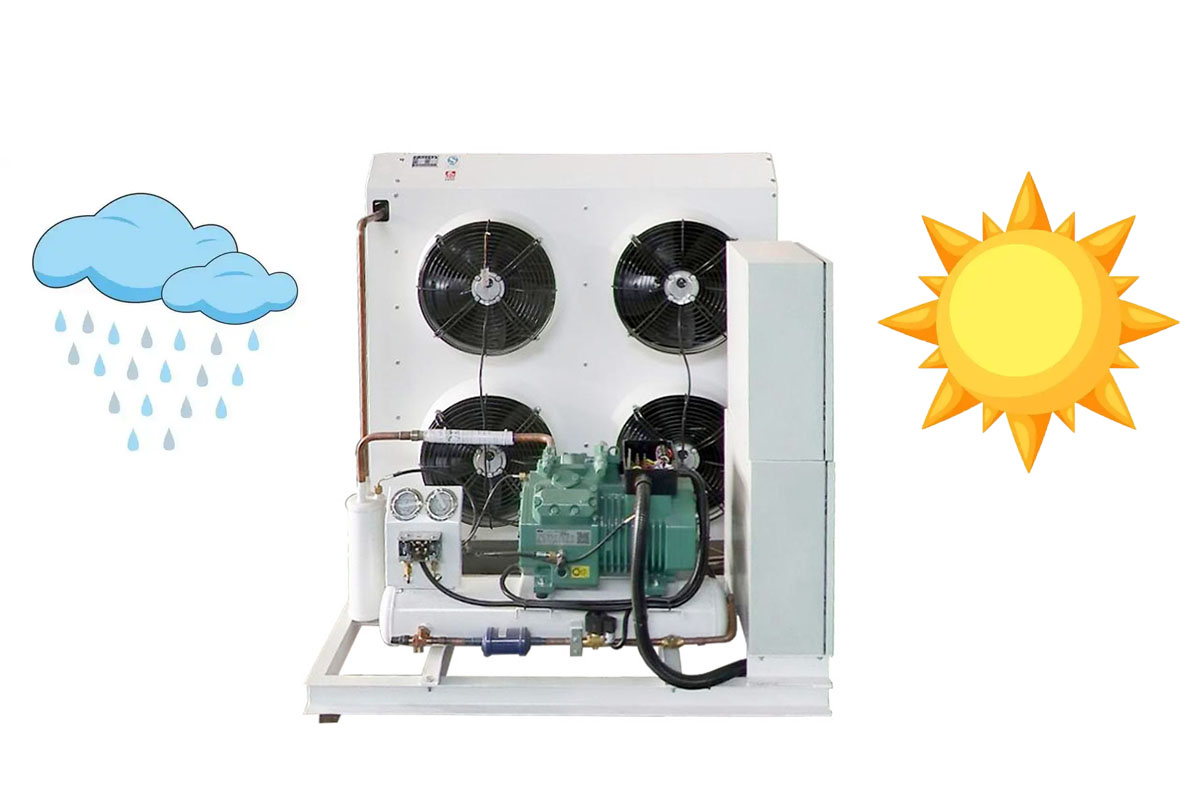

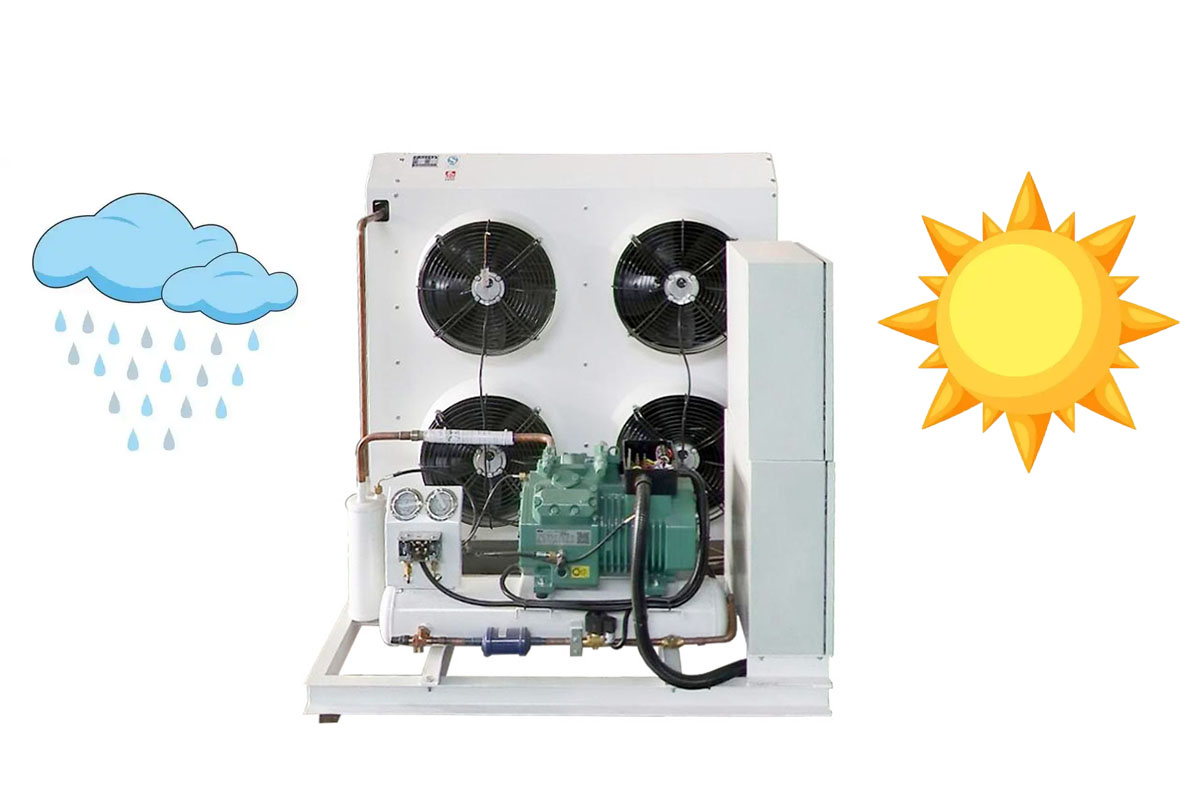

High temperature and humidity can significantly affect the efficiency of outdoor refrigeration units and even cause malfunctions. The following are the core protection points to help you balance device safety and heat dissipation efficiency.

Choose a professional sunshade: installed 60-80 centimeters directly above the unit, with an area exceeding 25% of the unit's projection, preferably made of aluminum alloy and weather resistant PC board (salt spray resistant in coastal areas); The height of the roof of the top outlet fan should be at least 1.5 meters away from the air outlet to avoid the backflow of hot air.

Careful selection of protective materials: Priority should be given to shells with low solar radiation absorption, paired with aluminum alloy heat dissipation fins and hydrophobic coatings.

Extreme high temperature: Reserved ventilation openings in the sunshade, combined with unit temperature control to form convective heat dissipation.

Basic installation: The base is higher than the local snow depth, and the concrete base is equipped with a drainage slope; Stainless steel fasteners with Dacromet coating for coastal use (stronger corrosion resistance).

Shell and dehumidification: choose electroplated galvanized steel plate+electrostatic powder coated shell (acid rain and salt spray resistant), use hydrophilic aluminum foil for heat exchanger; When the humidity exceeds 60%, install an intelligent dehumidification device and equip it with a constant temperature heater for extreme low temperatures.

Ventilation design: Open ventilation windows at the top and bottom to use hot air to rise and expel moisture; The distance between the back of the unit and the wall should be ≥ 20 centimeters, and both sides should be ≥ 15 centimeters to avoid enclosed spaces; The pipeline insulation layer is wrapped with galvanized iron sheet, and the welding joints are coated with acrylic resin.

Daily maintenance: Check the bracket fastening every quarter (add more points for high-rise buildings); Clear the ventilation outlet before the rainy season, and check the drainage holes to prevent icing in winter; Regularly flush the heat sink with low-pressure water (do not use high-pressure water); Coastal areas should check for metal corrosion every six months and promptly apply anti-corrosion coatings.

Sunscreen: Reduce energy consumption and prolong life

Direct sunlight can cause the surface of the unit to exceed 50 ℃, resulting in a 15% -20% increase in energy consumption and a decrease in efficiency with increasing temperature. Moderate shading is required:Choose a professional sunshade: installed 60-80 centimeters directly above the unit, with an area exceeding 25% of the unit's projection, preferably made of aluminum alloy and weather resistant PC board (salt spray resistant in coastal areas); The height of the roof of the top outlet fan should be at least 1.5 meters away from the air outlet to avoid the backflow of hot air.

Careful selection of protective materials: Priority should be given to shells with low solar radiation absorption, paired with aluminum alloy heat dissipation fins and hydrophobic coatings.

Extreme high temperature: Reserved ventilation openings in the sunshade, combined with unit temperature control to form convective heat dissipation.

Moisture prevention: anti-corrosion, anti short circuit

Moisture can easily cause metal corrosion and electrical faults. Although many units have IPX4-IPX5 waterproofing, additional protection is required:Basic installation: The base is higher than the local snow depth, and the concrete base is equipped with a drainage slope; Stainless steel fasteners with Dacromet coating for coastal use (stronger corrosion resistance).

Shell and dehumidification: choose electroplated galvanized steel plate+electrostatic powder coated shell (acid rain and salt spray resistant), use hydrophilic aluminum foil for heat exchanger; When the humidity exceeds 60%, install an intelligent dehumidification device and equip it with a constant temperature heater for extreme low temperatures.

Ventilation design: Open ventilation windows at the top and bottom to use hot air to rise and expel moisture; The distance between the back of the unit and the wall should be ≥ 20 centimeters, and both sides should be ≥ 15 centimeters to avoid enclosed spaces; The pipeline insulation layer is wrapped with galvanized iron sheet, and the welding joints are coated with acrylic resin.

Standards and Maintenance

Selection criteria: NEMA 3R standard for non canopy, IP65 grade for dusty and rainy conditions, installation in accordance with GB50243-2002 specifications. Daily maintenance: Check the bracket fastening every quarter (add more points for high-rise buildings); Clear the ventilation outlet before the rainy season, and check the drainage holes to prevent icing in winter; Regularly flush the heat sink with low-pressure water (do not use high-pressure water); Coastal areas should check for metal corrosion every six months and promptly apply anti-corrosion coatings.