With the rapid development of fresh e-commerce, cold chain logistics, and food processing industries, cold storage has become an indispensable part of the enterprise supply chain. However, many companies often waste resources or have insufficient capacity when purchasing or constructing cold storage due to unreasonable storage capacity and space planning. How to accurately estimate demand and design efficient cold storage space? This article will provide you with key recommendations.

Goods type: Different products (such as frozen meat, seafood, fruits and vegetables, or pharmaceuticals) have varying requirements for temperature, humidity, and stacking methods, which directly affect storage density.

Daily average inventory level: Based on historical data or business growth expectations, calculate the average inventory level and peak period increment, and reserve a buffer space of 10% -20%.

Turnover frequency: Goods with high-frequency turnover need to reserve more channels and operating space, while goods stored for a long time can optimize stacking methods.

Shelf and channel design: Using narrow aisle shelves (VNA) or drive in shelves can improve space utilization, but it needs to be matched with forklift types.

High utilization: Modern cold storage can be designed with a floor height of over 6 meters, combined with automated three-dimensional warehouses (AS/RS) to maximize vertical space.

Functional area division: Pre cooling area, sorting area, and storage area need to be independently planned to avoid cross contamination or temperature fluctuations.

Case: A fresh food enterprise lost over 5% of its goods annually due to frequent opening and closing of its cold storage due to the lack of a sorting area. After adding buffer rooms in the later renovation, energy consumption decreased by 15%.

Lack of flexibility: Modular cold storage or scalable design is more suitable for business growth needs.

By scientifically estimating storage capacity and optimizing space, enterprises can not only reduce operating costs, but also improve cold chain logistics efficiency and enhance market competitiveness.

Accurately estimate the storage capacity of goods

Before purchasing a cold storage, enterprises need to first clarify their storage needs:Goods type: Different products (such as frozen meat, seafood, fruits and vegetables, or pharmaceuticals) have varying requirements for temperature, humidity, and stacking methods, which directly affect storage density.

Daily average inventory level: Based on historical data or business growth expectations, calculate the average inventory level and peak period increment, and reserve a buffer space of 10% -20%.

Turnover frequency: Goods with high-frequency turnover need to reserve more channels and operating space, while goods stored for a long time can optimize stacking methods.

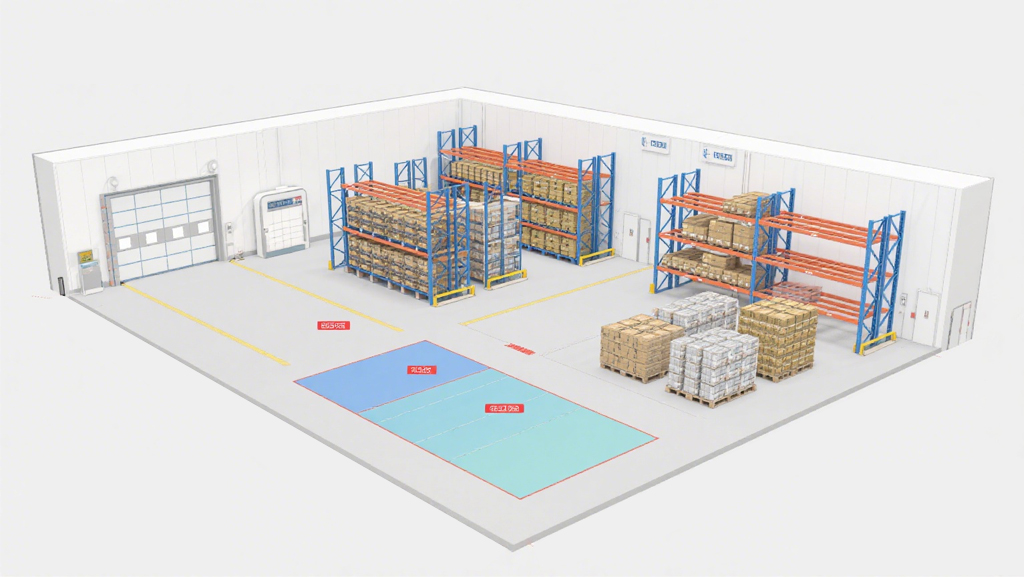

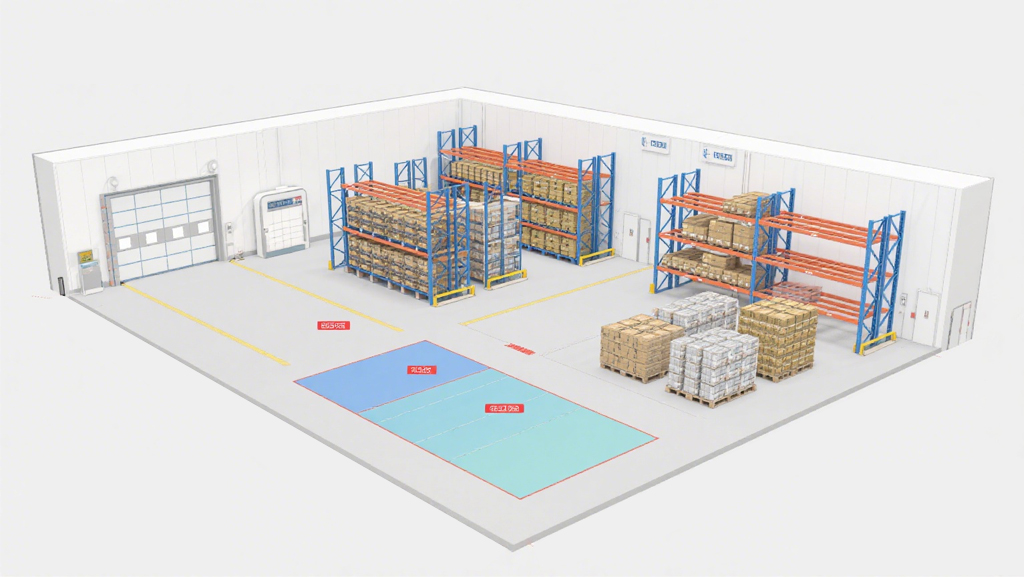

Reasonably plan the cold storage space

The larger the cold storage capacity, the better. It is necessary to balance storage efficiency and operating costs:Shelf and channel design: Using narrow aisle shelves (VNA) or drive in shelves can improve space utilization, but it needs to be matched with forklift types.

High utilization: Modern cold storage can be designed with a floor height of over 6 meters, combined with automated three-dimensional warehouses (AS/RS) to maximize vertical space.

Functional area division: Pre cooling area, sorting area, and storage area need to be independently planned to avoid cross contamination or temperature fluctuations.

Case: A fresh food enterprise lost over 5% of its goods annually due to frequent opening and closing of its cold storage due to the lack of a sorting area. After adding buffer rooms in the later renovation, energy consumption decreased by 15%.

Avoid common misconceptions

Overinvestment: Blindly choosing large capacity cold storage may lead to excessive energy consumption (cold storage energy consumption accounts for 30% -40% of operating costs).Lack of flexibility: Modular cold storage or scalable design is more suitable for business growth needs.

By scientifically estimating storage capacity and optimizing space, enterprises can not only reduce operating costs, but also improve cold chain logistics efficiency and enhance market competitiveness.