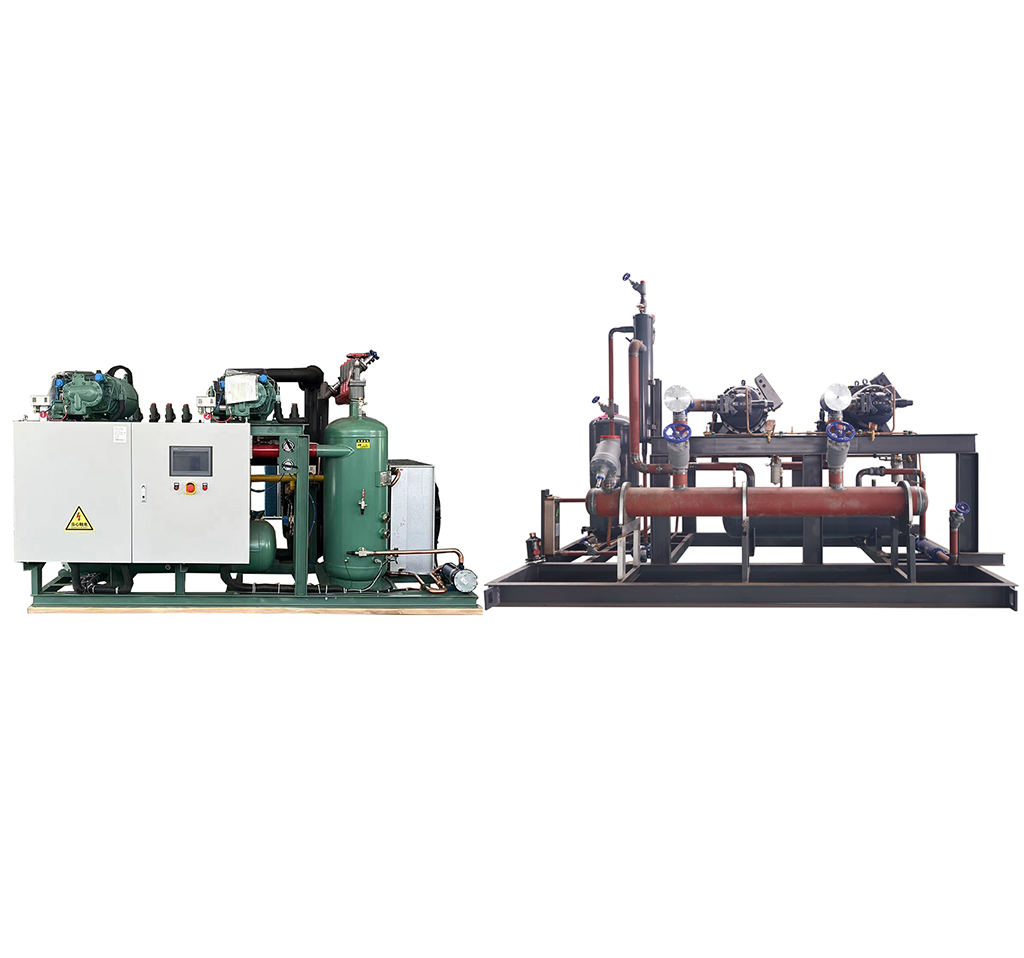

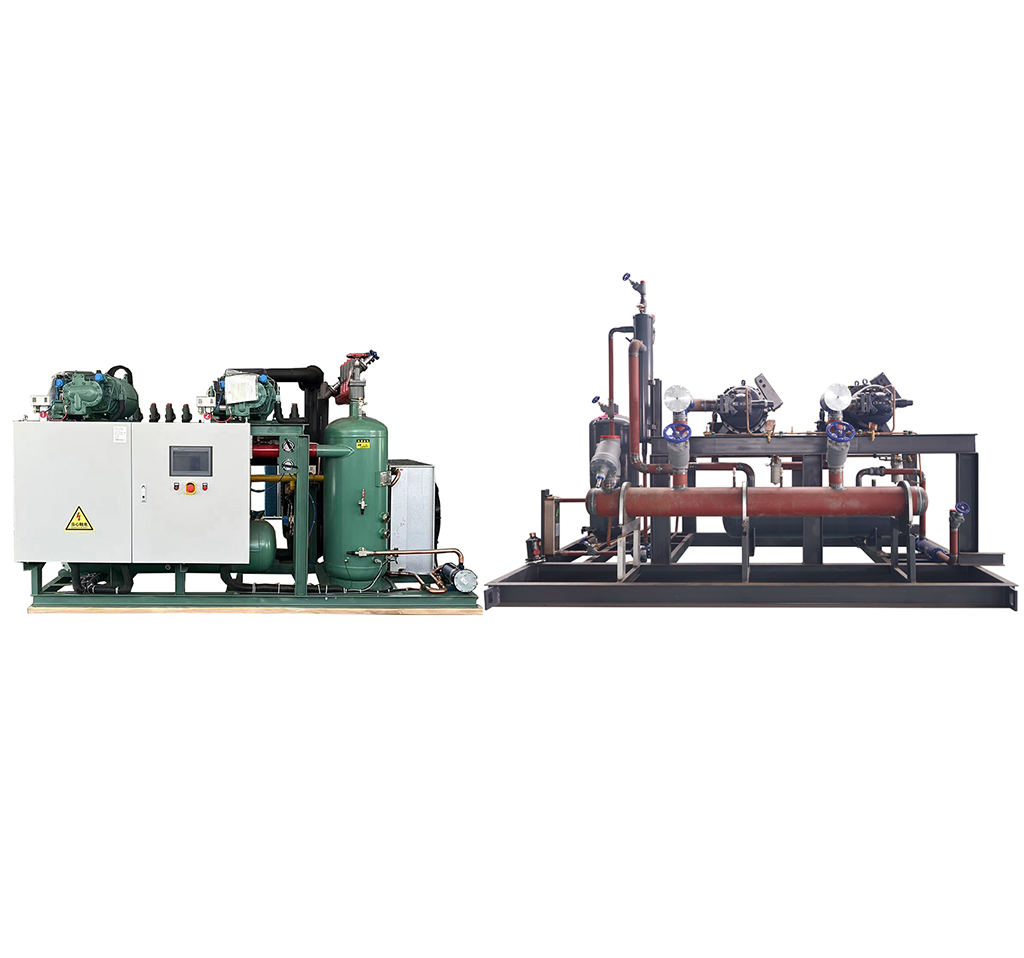

With the rapid growth of cold chain logistics and food refrigeration demand, screw units are gradually becoming the preferred solution for cold storage refrigeration systems due to their high efficiency, stability, and energy-saving advantages. More and more companies worldwide are adopting screw refrigeration units to replace traditional piston or scroll compressors, in order to improve energy efficiency and reduce operating costs.

Stable and reliable: With a simple structure and minimal wear, it is suitable for long-term continuous operation, especially for large cold storage facilities (such as logistics warehousing, food processing, and other industries).

Wide temperature range applicability: It can operate stably in a wide temperature range of -40 ℃ to 10 ℃, meeting the refrigeration and freezing needs of different cold storage facilities.

Intelligent control: Modern screw units integrate frequency conversion technology and Internet of Things (IoT) monitoring systems to achieve precise temperature control and remote operation and maintenance, further optimizing energy consumption management.

Medical storage: Medical cold storage requires extremely high temperature stability, and the precise temperature control capability of screw units makes it an ideal choice for storing vaccines and biologics.

Industrial refrigeration: In the fields of chemical engineering, frozen food processing, etc., large cooling screw units can meet the rapid cooling needs and improve production efficiency.

Advantages of screw unit

Efficient and energy-saving: The screw unit adopts advanced volumetric compression technology, which can still maintain a high COP (coefficient of performance) under low temperature conditions, saving 20% -30% energy compared to traditional refrigeration equipment.Stable and reliable: With a simple structure and minimal wear, it is suitable for long-term continuous operation, especially for large cold storage facilities (such as logistics warehousing, food processing, and other industries).

Wide temperature range applicability: It can operate stably in a wide temperature range of -40 ℃ to 10 ℃, meeting the refrigeration and freezing needs of different cold storage facilities.

Intelligent control: Modern screw units integrate frequency conversion technology and Internet of Things (IoT) monitoring systems to achieve precise temperature control and remote operation and maintenance, further optimizing energy consumption management.

Industry application cases

Food cold chain: An international fresh food supply chain enterprise upgraded its cold storage with screw units, resulting in a 25% reduction in annual electricity consumption and a 30% increase in refrigeration efficiency.Medical storage: Medical cold storage requires extremely high temperature stability, and the precise temperature control capability of screw units makes it an ideal choice for storing vaccines and biologics.

Industrial refrigeration: In the fields of chemical engineering, frozen food processing, etc., large cooling screw units can meet the rapid cooling needs and improve production efficiency.