The compressor, as the core component of the refrigeration system, directly impacts system performance, maintenance costs, and service life. This article will provide an in-depth analysis of the advantages and disadvantages of three mainstream compressor types—fully enclosed, semi-enclosed, and open—and focus on their maintenance costs and service life performance.

Common applications: household refrigerators, air conditioners, and small commercial refrigeration equipment

Typical capacity range: typically less than 10 horsepower

Common Applications: Medium-sized commercial refrigeration systems, industrial cooling equipment

Typical capacity range: 5-100 horsepower

Common applications: large industrial refrigeration systems, specific commercial settings

Typical capacity range: Generally greater than 20 horsepower

The operating noise is relatively low

Compact in structure, easy to install

No need for shaft sealing, completely eliminating the risk of refrigerant leakage

The manufacturing cost is relatively low

The heat dissipation performance is relatively poor

The power range is limited and not suitable for large-scale systems

The efficiency is generally lower than that of semi-enclosed counterparts at the same level

The heat dissipation performance is superior to that of fully enclosed types

Efficiency is generally higher than that of fully enclosed systems

Wide applicability and diverse capacity options

Partial repairs can be completed on-site

The noise level is higher than that of fully enclosed types

The initial investment cost is relatively high

Regular maintenance is required

The motor can be replaced individually, offering high flexibility

Optimal heat dissipation performance

Suitable for special working conditions and customized requirements

Theoretical service life is the longest (with proper maintenance)

The loudest noise

Belts or couplings are required, increasing maintenance points

High requirements for installation accuracy

Energy efficiency is typically the lowest (due to transmission losses)

Semi-enclosed: Moderate. Requires regular replacement of lubricants, filters, and seals

Open type: Maximum. Frequent inspection of shaft seals, belts, couplings, and alignment is required

Semi-enclosed type: Controllable and predictable. Replaceable wear parts such as valve plates and piston rings, with moderate cost

Open-type: Continuously high. Requires regular overhauls, but the cost per instance remains relatively reasonable after allocation

Semi-enclosed type: May require motor rewinding or comprehensive overhaul, but the cost remains lower than replacing the entire unit

Open type: Stable maintenance costs, with the lifespan extended indefinitely through periodic component replacement

Key finding: Although open compressors have the highest annual maintenance costs, their reparability suggests that the total holding cost may be the lowest over a 15-20 year cycle, particularly for high-power applications.

Semi-hermetic compressor: 12-20 years (designed with maintainability in mind)

Open-type compressor: 15-30 years or more (designed as a long-term maintainable equipment)

Open type: Sensitive to dust and humidity, but can be improved with protection

Semi-enclosed: Moderate maintenance can significantly extend lifespan

Open-type: Achieves ultra-long lifespan under strict maintenance

Semi-enclosed: offers better adaptability to load variations

Open type: Most suitable for variable load and heavy-duty applications

Limited equipment space

Hope for the lowest daily maintenance

Lower power demand (<10HP)

Plan to replace directly rather than repair in case of failure

Medium power demand (10-100HP)

Desired on-site repair capability

A good energy efficiency performance is required

Pursuing the longest service life

Capable of performing regular professional maintenance

Special application requirements (e.g., ammonia refrigerant)

The goal is to minimize the total lifecycle cost

Semi-hermetic compressor: New sealing technology and high-efficiency motor design reduce maintenance requirements

Open-type compressor: Leakage issues are being addressed with technologies like magnetic drive and shaftless sealing

Service Life: Under the same maintenance conditions, open compressors have the longest potential lifespan, followed by semi-hermetic ones, while fully hermetic compressors have the relatively shortest. However, actual lifespan heavily depends on operating conditions, load characteristics, and maintenance quality.

Final recommendation: There is no "absolutely best" compressor type, only the "most suitable" choice. For small commercial and household applications, fully enclosed compressors remain the optimal selection; for medium-sized commercial uses, semi-enclosed compressors offer the best balance; and for large industrial systems or scenarios requiring the longest service life, open compressors remain an irreplaceable option.

When making decisions, comprehensively consider the initial budget, operating conditions, maintenance capabilities, and long-term cost objectives. If necessary, consult a professional refrigeration engineer for a systematic evaluation.

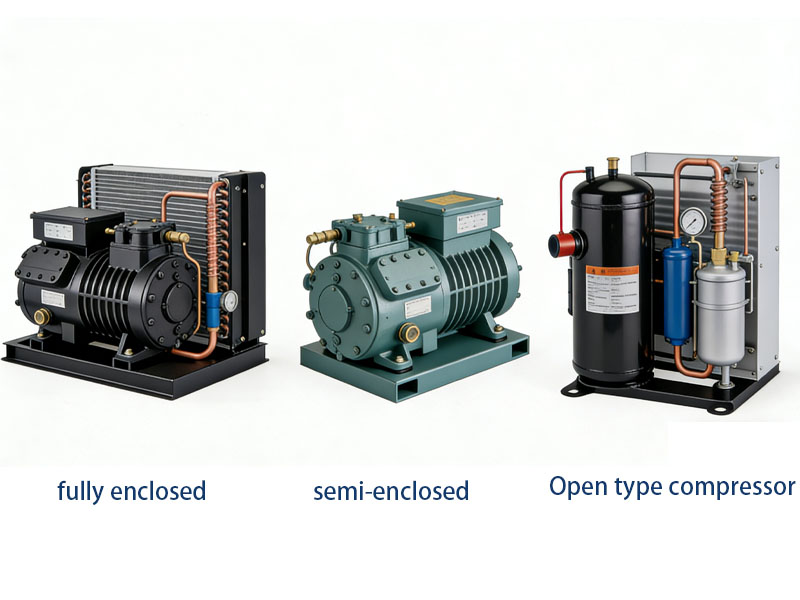

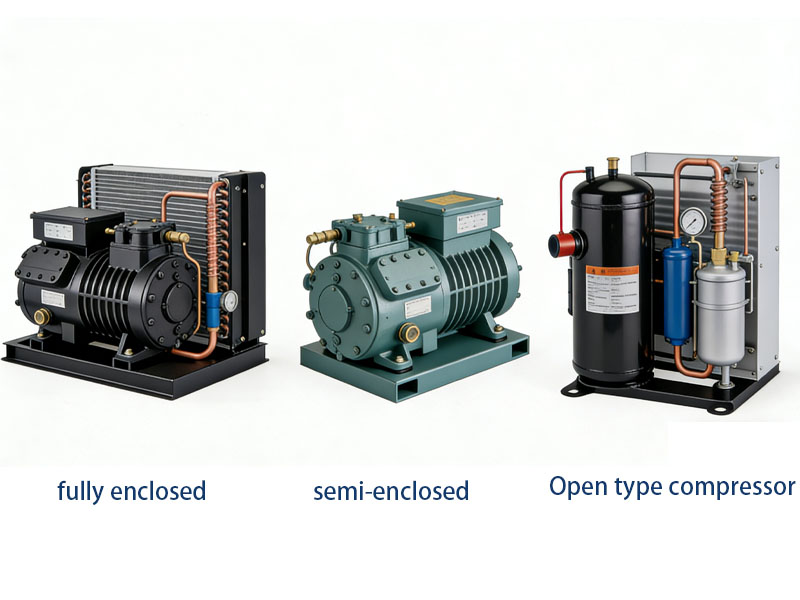

Overview of Three Compressor Types

1. Fully enclosed compressor

Structural Features: The motor and compressor are completely sealed within the same metal housing and are not detachableCommon applications: household refrigerators, air conditioners, and small commercial refrigeration equipment

Typical capacity range: typically less than 10 horsepower

2. Semi-hermetic compressor

Structural features: The fuselage and motor housing are connected via bolts, allowing for disassembly and maintenanceCommon Applications: Medium-sized commercial refrigeration systems, industrial cooling equipment

Typical capacity range: 5-100 horsepower

3. Open-type compressor

Structural characteristics: The compressor and motor are completely separated and connected via a shaftCommon applications: large industrial refrigeration systems, specific commercial settings

Typical capacity range: Generally greater than 20 horsepower

Comprehensive Comparison of Advantages and Disadvantages

Fully enclosed compressor

Advantages:

Fully sealed, with excellent dustproof and moistureproof performanceThe operating noise is relatively low

Compact in structure, easy to install

No need for shaft sealing, completely eliminating the risk of refrigerant leakage

The manufacturing cost is relatively low

Disadvantages:

Maintenance is extremely difficult, and the "replace rather than repair" strategy is typically adoptedThe heat dissipation performance is relatively poor

The power range is limited and not suitable for large-scale systems

The efficiency is generally lower than that of semi-enclosed counterparts at the same level

semi-hermetic compressor

Advantages:

High repairability with replaceable internal componentsThe heat dissipation performance is superior to that of fully enclosed types

Efficiency is generally higher than that of fully enclosed systems

Wide applicability and diverse capacity options

Partial repairs can be completed on-site

Disadvantages:

The shaft seal still exists, posing a potential leakage riskThe noise level is higher than that of fully enclosed types

The initial investment cost is relatively high

Regular maintenance is required

Open-type compressor

Advantages:

The most convenient for maintenance, with easy replacement of all componentsThe motor can be replaced individually, offering high flexibility

Optimal heat dissipation performance

Suitable for special working conditions and customized requirements

Theoretical service life is the longest (with proper maintenance)

Disadvantages:

The shaft seal is prone to leakage of refrigerant and lubricating oilThe loudest noise

Belts or couplings are required, increasing maintenance points

High requirements for installation accuracy

Energy efficiency is typically the lowest (due to transmission losses)

In-Depth Analysis of Maintenance Costs

Short-term maintenance costs (1-3 years)

Fully enclosed: Minimum. Typically requires only cleaning and electrical inspections, with very infrequent maintenance neededSemi-enclosed: Moderate. Requires regular replacement of lubricants, filters, and seals

Open type: Maximum. Frequent inspection of shaft seals, belts, couplings, and alignment is required

Mid-term maintenance costs (3-8 years)

Fully enclosed: May experience sudden increases. In case of failure, typically requires complete replacement, resulting in high costsSemi-enclosed type: Controllable and predictable. Replaceable wear parts such as valve plates and piston rings, with moderate cost

Open-type: Continuously high. Requires regular overhauls, but the cost per instance remains relatively reasonable after allocation

Long-term maintenance costs (over 8 years)

Fully enclosed: has been replaced, the new unit begins the cycle anewSemi-enclosed type: May require motor rewinding or comprehensive overhaul, but the cost remains lower than replacing the entire unit

Open type: Stable maintenance costs, with the lifespan extended indefinitely through periodic component replacement

Key finding: Although open compressors have the highest annual maintenance costs, their reparability suggests that the total holding cost may be the lowest over a 15-20 year cycle, particularly for high-power applications.

Lifespan Comparison

theoretical design lifespan

Fully enclosed compressor: 7-15 years (designed as a "one-time" product)Semi-hermetic compressor: 12-20 years (designed with maintainability in mind)

Open-type compressor: 15-30 years or more (designed as a long-term maintainable equipment)

Factors affecting actual service life

runtime environment

Fully enclosed: best tolerance to harsh environmentsOpen type: Sensitive to dust and humidity, but can be improved with protection

Maintenance level

Fully enclosed: Minimal maintenance required, but lifespan ends immediately upon failureSemi-enclosed: Moderate maintenance can significantly extend lifespan

Open-type: Achieves ultra-long lifespan under strict maintenance

Run load

Fully enclosed: Suitable for stable loads, lifespan shortened with significant fluctuationsSemi-enclosed: offers better adaptability to load variations

Open type: Most suitable for variable load and heavy-duty applications

How to Choose the Appropriate Compressor Type?

Choose fully enclosed when:

Initial investment budget is limitedLimited equipment space

Hope for the lowest daily maintenance

Lower power demand (<10HP)

Plan to replace directly rather than repair in case of failure

Choose the semi-enclosed type when:

Striving for the optimal balance between maintenance costs and lifespanMedium power demand (10-100HP)

Desired on-site repair capability

A good energy efficiency performance is required

Select the open mode when:

Ultra-high power demand (>50HP)Pursuing the longest service life

Capable of performing regular professional maintenance

Special application requirements (e.g., ammonia refrigerant)

The goal is to minimize the total lifecycle cost

Latest Technological Development Trends

Fully enclosed compressors: Inverter technology and new materials are extending their lifespan and broadening their application scopeSemi-hermetic compressor: New sealing technology and high-efficiency motor design reduce maintenance requirements

Open-type compressor: Leakage issues are being addressed with technologies like magnetic drive and shaftless sealing

Conclusion

Maintenance cost: In the short term, fully enclosed compressors have the lowest costs; however, from a complete lifecycle perspective, semi-enclosed and open compressors may achieve lower total cost of ownership through controlled maintenance investments.Service Life: Under the same maintenance conditions, open compressors have the longest potential lifespan, followed by semi-hermetic ones, while fully hermetic compressors have the relatively shortest. However, actual lifespan heavily depends on operating conditions, load characteristics, and maintenance quality.

Final recommendation: There is no "absolutely best" compressor type, only the "most suitable" choice. For small commercial and household applications, fully enclosed compressors remain the optimal selection; for medium-sized commercial uses, semi-enclosed compressors offer the best balance; and for large industrial systems or scenarios requiring the longest service life, open compressors remain an irreplaceable option.

When making decisions, comprehensively consider the initial budget, operating conditions, maintenance capabilities, and long-term cost objectives. If necessary, consult a professional refrigeration engineer for a systematic evaluation.